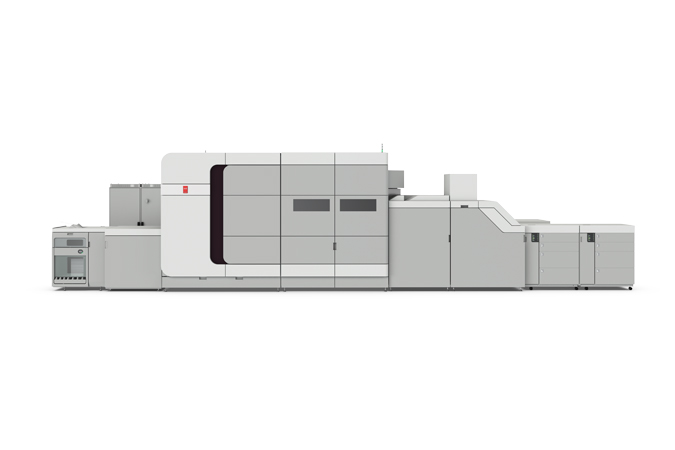

VarioPrint i-series+

Combining the reduced costs of inkjet with the media and application flexibility of sheet-fed production, the VarioPrint i-series+ provides an advantageous proposition to print providers who are looking to grow their business by:

-

- Cost effectively running monochrome and color jobs on one engine

-

- Moving mono applications to higher-value/higher-margin color products

-

- Extending the cross over point for digital print versus offset, helping more pages migrate to digital print

Enjoy peak productivity

Leveraging print head technology from the proven ColorStream inkjet web presses, the VarioPrint i-series+ provides 600 x 600 dpi output with drop size modulation to deliver 1,200 dpi perceived image quality. Automated inline quality control detects nozzle failure and automatically applies compensation to help maintain quality.

Maximizing uptime

Uptime is crucial to meet today’s demanding SLAs. For VarioPrint i-series+, uptime is enhanced by automated maintenance routines which help secure uninterrupted production; simultaneously helping maintain print quality, productivity and uptime. Engineered with “Sense and Support” maintenance, the VarioPrint i-series+ helps minimize unplanned service activities and optimize planned maintenance.

Drive Press efficiency

The scalable, high performance PRISMAsync controller allows users to plan jobs ahead of time and provide adequate information to help keep the machine running without unplanned stops.

Specifications

VarioPrint i-series+ |

||||||||||||||||

Main Engine |

||||||||||||||||

| Printer Type: | Sheetfed color inkjet press | |||||||||||||||

| Technology: | Drop-on-demand piezoelectric inkjet technology | |||||||||||||||

| Ink: | iQuarius aqueous pigment inks | |||||||||||||||

| Inkjet print head: | Kyocera KJ4B, VarioPrint i300 optimized | |||||||||||||||

| Colors: | CMYK standard, print order YMCK | |||||||||||||||

| Print Resolution: | 600 x 600 dpi, drop size modulation for 1200 dpi perceived image quality in images and halftones | |||||||||||||||

| Monthly Target Volume: | 1 to 10 Million letter images | |||||||||||||||

| Maximum Print Speed (ipm): | Duplex printing/simplex printing | |||||||||||||||

|

||||||||||||||||

| Paper Size*: | ||||||||||||||||

| Minimum: 8″ x 8″ Maximum: 12.6″ x 19.2″ Optional Support: Statement size (7″ x 10″) 13.9″ x 19.7″** |

||||||||||||||||

| Maximum Imageable Area: | 12.7″ x 19.5″ | |||||||||||||||

| Print Distance from Edge: | 08″ (2 mm) from each edge | |||||||||||||||

| Paper Weight*: | 40lb Offset to 110lb Cover (60-300 gsm)*** | |||||||||||||||

| Substrates: | Offset uncoated, Offset coated, Inkjet treated, Inkjet pigmented and Inkjet coated | |||||||||||||||

Paper Input |

||||||||||||||||

| Maximum 3 PIM, any combination PIM or Flex PIM-XL**** | ||||||||||||||||

| Paper Input Module (PIM) | ||||||||||||||||

| Paper Feeding Technology: | Air Separation, Suction Feeding, Paper Conditioning | |||||||||||||||

| Capacity: | 4,600 Sheets (20 lb. Bond) | |||||||||||||||

| Tray 1 and 2: 600 Sheets (20 lb. Bond) Tray 3 and 4: 1,700 Sheets Standard (20 lb bond) Maximum: 13,800 sheets (3 x 4600 20 lb. bond) |

||||||||||||||||

| Paper Sizes (all trays): | 8″ x 8″ to 12.6″ x 19.2″ | |||||||||||||||

| Dimensions (H x W x D): | 37.2″ x 30.3″ x 23.5″ (1150 mm x 922 mm x 716mm) | |||||||||||||||

| Weight: | 485lbs (220kg) | |||||||||||||||

| Paper Input Module (Flex PIM XL) | ||||||||||||||||

| Paper Feeding Technology: | Air Separation, Suction Feeding, Paper conditioning | |||||||||||||||

| Capacity: | 4,600 Sheets (20 lb. Bond) | |||||||||||||||

| Tray 1 and 2: 600 Sheets (20 lb. Bond) Tray 3 and 4: 1,700 Sheets Standard (20 lb bond) Maximum: 13,800 sheets (3 x 4600 20 lb. bond) |

||||||||||||||||

| Paper Sizes: | Tray 1: 8″ x 8″ to 12.6″ x 19.2″ Tray 2,3, and 4: 8″ x 8″ to 13″ x 19.7″ |

|||||||||||||||

| Dimensions (H x W x D): | 37.2″ x 30.3″ x 23.5″ (1150 mm x 922 mm x 716mm) | |||||||||||||||

| Weight: | 485lbs (220kg) | |||||||||||||||

Paper Output |

||||||||||||||||

| High-Capacity Stacker | Main Trays: 6,000 Sheets(2 Stacks x 3,000 Sheets – 20 lb. Bond) Top Tray: 200 Sheets |

|||||||||||||||

| Maximum 2 High-Capacity Stackers: | 12,000 Sheets | |||||||||||||||

| DFD Interface (Optional): | For Integration with Third-party Finishing | |||||||||||||||

| Dimensions (H x W x D): | 34.1″ x29.5″ x 24.4″ (1040mm x 899mm x 745mm) With tray ejected: 34.1″ x 41.0″ x 24.4″ (1040mm x1250mm x 745mm) |

|||||||||||||||

| Weight: | 265 lbs. (120 kg) | |||||||||||||||

| Environment | ||||||||||||||||

| Temperature: | Optimal range 68°-79° F (20° to 26° C) | |||||||||||||||

| Relative Humidity: | Optimal range 30-50% RH | |||||||||||||||

| Atmospheric Pressure Range: | 840-1,060mbar (maximum altitude 5,000 ft. (1500m) above sea level) | |||||||||||||||

| Noise Emissions: | Operation: 73 dB Standby: 61dB | |||||||||||||||

| Electrical Requirements | ||||||||||||||||

| Power Consumption | During Printing: < 50 kW | |||||||||||||||

Print Operation Management |

||||||||||||||||

| PRISMAsync Controller | ||||||||||||||||

| Server Type: | External | |||||||||||||||

| Operating System: | Windows 10 | |||||||||||||||

| RIP Clients: | 2 Standard (Up to 2 Optional, 4 Max) | |||||||||||||||

| Supported PDLs: | Document Printing: PS, PDF 1.7, Extension Level 3 (for Acrobat 9); PDF/X (APPE 3.2 RIP support) Variable Data Printing: PDF/VT (Level 1) Transactional Printing: Native IPDS (IS/3 compliant; APPE 3.1 for PDF color management in transaction mode) |

|||||||||||||||

| Standard License Bundle: | 1 x PDL (PDF or IPDS); Scheduler; Remote Viewer; Trapping; Streaming; Accounting; Hot Folders; Remote Service; E-shredding; Advanced Color Management, PRISMAylitics | |||||||||||||||

| Optional Licenses: | Additional PDL (PDF or IPDS); PDF for IPDS | |||||||||||||||

| PRISMA Workflow Modules (optional): | PRISMAproduction PRISMAprepare | |||||||||||||||

| Network Connectivity: | 2 x 10 gigabit Ethernet (10/100/1000 Base T), TCP/IP (LPR/LPD,9100 Socket,SMB),Static IP/Auto IP (DHCP), IPv4, IPv6 (only in Document Printing mode) | |||||||||||||||

| Protocols: | SNMP v1, SNMP v3, Host Resources MIB, MIB II, Printer MIB, Job Monitoring MIB, Job Management MIB | |||||||||||||||

| Physical Data | 2 PIM/1 HCS | |||||||||||||||

| Dimensions (H x W X D): | 7.5′ x 30.5′ x 9.2′ (2.3 m x 9.3m x 2.8 m) | |||||||||||||||

| Minimal Space Required (service clearance): | 7.5′ x 30.5′ x 9.2′ (2.3 m x 9.3m x 2.8 m) | |||||||||||||||

| Floor Space (W x D): | 34.8′ x 21.3′ (10.5 m x 6.5 m) | |||||||||||||||

| Height: | 9.8′ (3 m) | |||||||||||||||

| Volume: | 7239.5 ft3 (205 m3) | |||||||||||||||

| Weight: | 17,968 lbs (8150 kg) | |||||||||||||||

| Maximum Floor Load (Point load): | 12N/mm2 or 1,740 psi | |||||||||||||||

| * Paper size and weight specifications apply for PIM, Main Engine and HCS ** Requires FLEX PIM XL option *** Supported media weight depends on used media. **** 2nd and 3rd PIM Optional |

||||||||||||||||

- iQuarius technologies empower high-speed, sheet-fed inkjet versatility:

- iQuarius proprietary CMYK inks provide outstanding quality and productivity with a broad color gamut, print robustness, and media compatibility at low inkjet cost.

- Optional Magnetic Ink Character Recognition (MICR) integrated print heads to support both high-volume color inkjet printing and MICR applications on a single platform.

- Sheet Entry Control via the Sentry unit provides full-speed automated detection of any paper deformations that could lead to a print head touch, purging sheets without interrupting production.

- Precision Sheet Control is provided by a seamless metal belt that holds inkjet imaged sheets flat with air suction, helping move them smoothly, precisely and at high speed through the press.

- An iQuarius Drying System uses four distinct drying principles at once: induction-heated drum; carbon infrared radiation (CIR); air impingement; and air suction – producing a high-quality, robust printed product.

- An Inline Quality Control system prints a test/nozzle failure detection sheet at regular intervals (operator configurable) and scans it in-line applying compensation when needed, automatically to help maintain quality.

- Print head technology from the industry leading ColorStream delivers up to 80 million drops per second while providing precision imaging at 600 x 600 dpi with multilevel drop size modulation for image quality with the visual perception of 1,200 dpi.

- Media input and output technologies from the market proven VarioPrint 6000+ series provides reliable, high-performance feeding with air separation and suction feeding along with seamless tray switching and true “all media from all trays” capability*.

- Proven PRISMAsync controller platform offers intuitive operation and intelligent media management helping drive maximum productivity. PRISMAsync handles native PDF and IPDS/AFP data input and combined with PRISMA workflow software it enables workflow alignment within the shop for maximum efficiency and productivity.

- Auto-maintenance routines including automatic print head refresh modes and print head maintenance during operation help maintain optimal quality and productivity while helping reduce operator intervention.

- “Sense and Support” predictive maintenance helps to minimize operator intervention and maximize uptime.